Architectural Metal Solutions

Our Heritage

In 1932, Stuart Dean pioneered the restoration and preservation of non-ferrous ornamental metal, America’s original on-site restoration and maintenance Company. Through experience, research and development in new technology, Stuart Dean has become the premier solution provider for architectural metal challenges in our modern-day world of abrasion, pollution and acid rain environs. This paper is primarily an overview of Copper Alloys, which have been widely used throughout the world in architecture and design since 3000 BC. Informed by our 78 years of direct experience, this white paper identifies solutions for chemical coloring and preservation due to natural weathering, deterioration and graffiti.

What are Architectural Metals

Ornamental building materials – especially bronze, nickel/silver, brass, stainless steel, aluminum, iron and most recently titanium – are used in highly visible areas. They were incorporated in the architectural design to evoke a sense of style, prestige, success, strength, wealth, and power in public areas. Most architectural metal applications are found in non-residential projects such as commercial buildings, institutions, government buildings, universities, transportation facilities, corporate offices, hotels and shopping centers. In order to maintain this image for owners and their customers and tenants, it is paramount to continually reaffirm this representation of the facility’s identity and brand image.

The popularity of metals among architects is not surprising. It’s a continuing trend that began millenniums ago. But first, a brief review of metallurgy will help you understand why architects and specifiers choose copper alloy ornamental metal for their designs.

Metal Composition of Copper Alloys

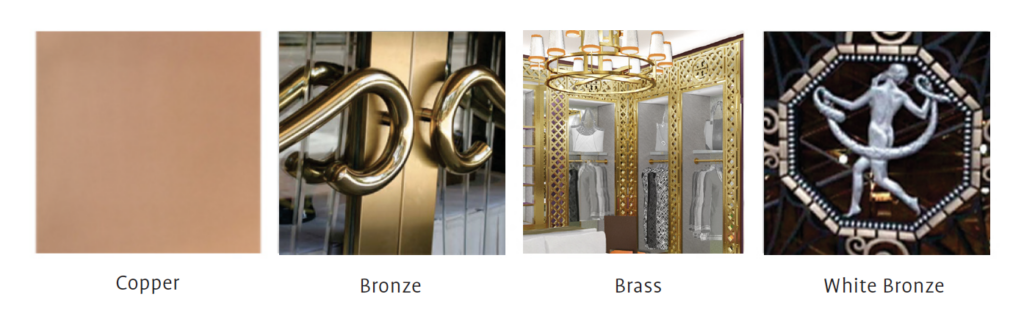

Copper is a natural ore, is very durable, and when combined with other elements, produces Bronze, Brass and Nickel Silver.

“True” bronze is composed of approximately 90% copper and 10% tin, and is a rich pink metal. Any copper alloy that contains zinc is actually brass, but often marketed as bronze. The three types of so-called bronze most used for architectural purposes are: “statuary bronze,” “architectural bronze” and “commercial bronze.” Today, of these, only statuary bronze is close in composition to a true bronze, one containing copper, tin and zinc.

Nickel silver is a class of nickel alloys, none of which contain any silver. Rather, it gets its name from its silver-white color. Its composition is similar to brass with nickel added (sometimes referred to as “white bronze,” Monell Bronze, German Nickel or Benedict Nickel). The proportions vary from 5-30% nickel, 10-35% zinc, and 50-80% copper.

Why have copper alloys stood the test of time to remain a popular choice of architects even today? These surfaces can give a building a unique and powerful character, they’re very versatile, and are often easy to repair. And they grow more attractive with age.

Why have copper alloys stood the test of time to remain a popular choice of architects even today? These surfaces can give a building a unique and powerful character, they’re very versatile, and are often easy to repair. And they grow more attractive with age.

If allowed to weather naturally, copper, bronze, brass and nickel silver develop a unique patina. partially dependent on geographic location and atmospheric conditions. As the alloy ages, the patina continually takes on new color characteristics and further enhances the look of a building. If damaged by scratches, most often Stuart Dean can remove these on-site, depending on the severity.

This ability to change color is both good and bad for the architect and property owner.

Copper Alloy’s Chameleon Properties

What is “patina” on copper? A copper sulfate film forms on the surface, this oxidation process changes from a “bright penny” color through a progression of russet browns, grays, and finally to a blue-green or gray-green patina. It acts as a protective coating against further reaction with the atmosphere. It can form on pure copper objects as well as alloys that contain copper, such as bronze or brass. A patina layer takes many years to develop under natural weathering.

Industrial Seacoast……. 5 – 8 years

City – Industrial…………… 8 – 12 years

Typical City Region………. 15 – 20 years

Bucolic, Mountain………. > 30 years

Dry Desert Region………. Indefinite

Copper Alloys (Bronze, Brass, and Nickel Silver) will take the same or longer, depending on the copper content of the alloy. But the process can be uneven due to pollution and acid rain.

Stuart Dean artisan technicians have been trained to accelerate the aging process of copper alloys through chemicals and can achieve a variety of patinas. Stuart Dean’s founder, Edward Degan, had a saying, “I can only give you what the metal gives me.” Basically, he was saying the materials used for smelting bronze (copper, tin, zinc, lead, silicone) will determine the color that can be achieved. For example, copper allows for coloring, sometimes called oxidized. Zinc, on the other hand, is an inhibitor of oxidation. Oxidize coloring can range from light yellow-brown to brown-black.

The color is enhanced by lacquers or clear-coatings. Early in the 20th century, Stuart Dean was the first metal refinishing company to incorporate DuPont Lacquers in our refinishing process to protect bronze from tarnishing – thereby eliminating countless hours of daily polishing. We continue to research new protective coatings that are environmentally friendly, such as waterborne clear coatings and other longer-wear type coatings.

Frequently Used Architectural Finishes

Standard Mill Finish – Weather hot or cold rolled are the basic supplied panel finishes. This finish cannot be duplicated on site.

Mechanical Finish – Sometimes referred to as brushed metal, this metal that has been abraded, usually with sandpaper. Brushing gives the metal a distinctive look of very fine lines, several small scratches all running in the same direction. The finish is a factory finish and cannot be duplicated on- site.

Another brush finish is a belt-sanded finish. The advantage of this finish is that the grain is continuous and runs the length of the sheet. The importance of a continuous long grain strap-sanded finish is to allow for repair of minor scratches and on-site refinishing.

No. 4 Satin Finish – This is a unidirectional finish obtained with 150-to-240 grit abrasives. It is not highly reflective, is widely used in commercial architecture, and can be easily refinished on site.

No. 8 Mirror Finish – This is produced by using progressively finer and finer abrasives, the final operations being done with extremely fine buffing compounds. The final surface is blemish-free with a high degree of image clarity, and is a true mirror finish, and can be refinished on-site.

Specialty Finishes

Random Grain Finish – Here, special grinding techniques are used to provide a variety of finishes. While some mechanical finishes cannot be replicated on-site, the Stuart Dean Research and Development Department can create a random grain on an existing satin or mirror finish on-site.

Angel Hair Finish – A dull satin finish with low reflectivity, possessing no directional grain.

Copper Alloy Coloring Finishes

Coloring is an art – mainly a matter of craftsmanship and experience. Chemical coloring techniques depend on time, temperature, surface preparation, humidity and other variables that influence the ultimate result.

Natural Satin: The natural color of bronze, a bright golden hue. The surface is prepared with a dull, sanded, grain look.

US 10 Statuary: This is the most widely used patina finish historically. A statuary finish is a rich, deep brown color and can be varied anywhere from light to medium to dark.

2-Tone Finish: Is a combination of US10 Statuary with the surface highlighted, showing the natural color in areas to achieve depth and contrast. This effect can also be achieved with Bronze Powders for background color.

Vertigris Finish: This green, very rustic finish is reflective of the large amounts of copper in the bronze alloy. This is the most difficult and costly of the finishes because of the delicate nature of the finish.

Protective Clear Coatings

Frequently, customers want to preserve the finished tones of their copper or brass surfaces. We do this by applying clear protective coatings, which create a weather barrier and prevent the further oxidation of copper, brass and bronze surfaces.

However, as with any coating, degradation over time will require stripping and replacing the clear coating.

Causes of Architectural Metal Deterioration

Properly selected, installed, and maintained architectural metal elements are among the most durable and permanent building materials. However, metal elements that are not properly suited for the chosen function, or are not properly cared for, can be very fragile and short lived.

Corrosion

Corrosion in one form or another is the major cause of the deterioration of architectural metals. Often called oxidation, it is the chemical reaction of a metal with oxygen, pollutants or other substances. This can occur from natural weathering where the humidity level is high, industrial agents mixed with oxygen and water to produce acid rain and moisture, or exposure to sea water, which contains chlorides and other salt particles that can be deposited on the surface of the metal.

Abrasion

Human abrasion is another form of deterioration. A common example of abrasion is seen on door handles and railings, where the dirt, oil and minute amounts of acid from the hands are in contact with the metal surface, showing as wear and superficial discoloration. Rings and other jewelry will often abrade the surface in the form of scratches.

Copper alloys can be attacked by alkalis, ammonia and various sulfate compounds that can combine with water to form sulfuric acid.

Excrement from birds or other animals is acidic and can also damage copper alloys.

Dezincification Corrosion

Dezincification is a kind of corrosion particular to brass or bronze with a composition of more than 15% zinc. This occurs where acids and other strongly conducting solutions are present. The zinc will get extracted from the brass due to the water chemistry attacking the zinc. The copper-zinc alloy is dissolved, the copper is re-deposited electrochemically, and the zinc either remains in solution or its compound forms a scale. Dezincification may leave the metal pitted, porous, and/or weak, depending on the extent and severity of the corrosion. Dezincification can occur from improper cleaning methods, and the result can be a variety of color from gold to green to orange. This form of corrosion occurs when the metals in brass (copper and zinc) become separated from each other.

Scratch Removal

- Scratch removal in copper, bronze, brass and nickel silver is as follows, if the cut is not extremely deep:

- Stripping all foreign matter (including all protective coatings), removing the scratch either by sandpaper, acrylic pad or cutting rouge, depending on the type of finish desired.

- Cleaning the surface thoroughly to remove all traces of oils from hands or materials, polish, if refinishing to a #8, Mirror finish.

- If the surface is oxidized, the metal will need to be re-oxidized after the scratch is removed.

- If the metal has a sandblast or etched design that has been disturbed, it may need to be re-etched or sandblasted.

This process may not be able to be done in the field. The metal skin must be removed and replaced if the design cannot be duplicated. And a protective coating if necessary or desired. As stated earlier, copper alloys are tarnishable metals, and the only thing that protects and retards this tarnishing is a protective coating. If the cut is not repairable the metal surface would need to be replaced or restored to a different finish, for example, polished to satin.

Preservation Methods

Metal components in temperature-controlled environments corrode less rapidly than metals exposed to the natural environment. Without a coating, a natural patina forms, causing a slow color change (sometimes referred to as tarnishing) from gold to brown to black. On exteriors, the colors are usually uneven and streaked because of the local pattern of wind and rain. The proper cleaning of copper alloys with mild chemicals and abrasives can return them to their natural color. To accelerate and achieve a uniform oxidize finish, the metal is cleaned and chemically treated to bring out an oxidized color. A clear coating must be applied to preserve the natural or oxidized color, and this should not be considered a “do-it-yourself” project.

Stuart Dean has over 75 years of experience restoring and preserving copper alloys. Our Research and Development and Training Center, located in Cleveland, Ohio, is devoted to developing new and improved processes and products for architectural building surfaces through cutting-edge technologies. The condition of architectural building materials should be assessed by a competent professional. Stuart Dean’s 100 sales and support staff are fully trained for this purpose. It is very specialized work, and Stuart Dean University provides expert hands-on industry training to each of our 500 technicians in restoration, preservation and conservation.

Summary

Preservation: Preventative Maintenance is the Key

KlingStubbins’ Castner identifies copper alloys as being associated with high-end buildings. “Because of the expense involved,” he says, “these alloys were associated with projects that were high quality, where cost was less of an issue.”

The Benefit of Maintenance on architectural metal is to prolong and preserve the life and aesthetics of building materials. The copper, bronze, brass and nickel silver building materials discussed here have been used in highly visible public areas.

Periodic restoration and maintenance is the only way to reaffirm the image envisioned in the design of the premise.

Building Services provide basic tenant necessities (i.e. lighting, heating, janitorial etc.), but often neglected are those key aesthetic appointments that set one building, store or restaurant apart from another. The economic benefits of maintenance and restoration are curb-side or aesthetic appeal, and asset value protection throughout the building’s useful life.

The purpose for overall maintenance of the building is to attract prospective tenants or customers, to satisfy and retain existing tenants or returning customers, and to protect and increase the owners’ asset value.

Stuart Dean has worked hand in hand with managers to tailor comprehensive refinishing and maintenance programs that keep their facilities’ image in pristine condition at all times.

If you would like to find out more on how Stuart Dean can help you and your architectural building materials, please contact one of our 14 divisions located throughout the U.S. and Canada.